Americans on average eat more than 150 million servings of chicken every day and virtually all of them are eaten safely. But we want 100% of them to be eaten safely.

Poultry companies have invested tens of millions of dollars in technology and other scientifically-validated measures to enhance the safety profile of chicken products. Continuous inspection and testing by FSIS has demonstrated the long-term success of these interventions in providing a safe, wholesome and affordable protein for consumers.

1. It all starts even before the egg. Breeder hens—who produce the eggs—are attended to carefully and humanely. Healthy breeder hens lead to healthy eggs and eventually, healthy chicks. Additional measures are taken to ensure the chicks inherit the hens’ maternal antibodies while preventing the sharing of any diseases.

2. At the hatchery where the chicks are hatched, strict sanitation measures and appropriate vaccinations ensure the chicks are off to a healthy start. At the feed mill, the corn and soybean meal that the chickens eat is heat treated, killing any bacteria that may be present. And on the farm, veterinarians and strict biosecurity measures ensure chickens are safe and healthy.

3. At the processing facility, the U.S. federal meat and poultry inspection system complements efforts by chicken processors to ensure that every single chicken product is safe, wholesome and correctly labeled and packaged. U.S. Department of Agriculture inspectors are present in every facility that processes chickens – it is required by law.)

These efforts at the processing facility include: organic rinses that cleanse the chicken, reducing any potential foodborne pathogens or bacteria; keeping the meat at the proper cool temperature; and using metal detectors and x-rays to make sure that no foreign object makes its way into a product or package. Microbiological tests are conducted on the products by both the companies and federal laboratories to help ensure that food safety systems are working properly and that each and every final product meets USDA standards for wholesomeness.

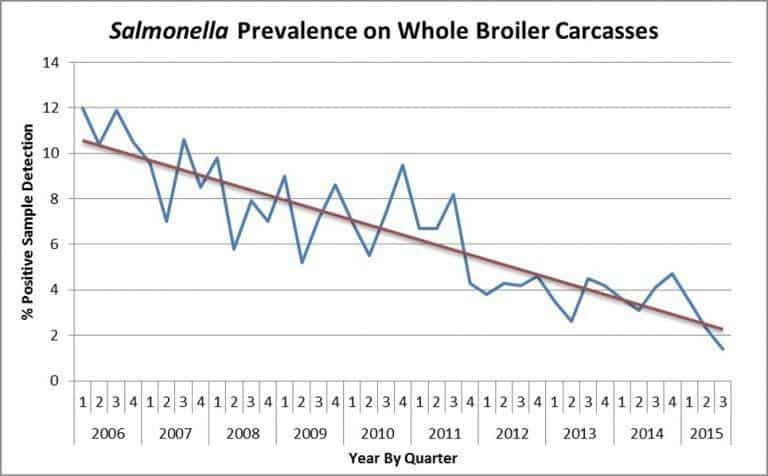

These efforts are netting tangible results.

Government testing shows levels of Salmonella on raw chicken are at all-time lows. According to USDA’s Food Safety and Inspection Service (FSIS), 94% of large establishments are meeting the recently-tightened USDA performance standard for Salmonella on whole broiler carcasses. Similarly, almost 95% of large establishments are meeting the FSIS performance standard for Salmonella on chicken parts, like wings, breasts and drumsticks.

But raw chicken, just like any other raw agricultural commodity, is not a sterile product. Even with very low levels of Salmonella, there is still the possibility of illness if a raw product is improperly handled or cooked. Proper handling and cooking of poultry is the one silver bullet that will eliminate any risk of foodborne illness. All bacteria potentially found on raw chicken are fully destroyed by handling the product properly and cooking it to an internal temperature of 165°.

Federal Inspection

The Food Safety and Inspection Service (FSIS) is the public health agency in United States Department of Agriculture (USDA) that is responsible for inspection at broiler chicken processing facilities (those facilities that process chickens for meat). The U.S. meat and poultry inspection system complements industry efforts to ensure that the nation’s commercial supply of meat, poultry and egg products is safe, wholesome and correctly labeled and packaged.

Food safety standards are applied to all chicken products produced in the United States and countries that import chicken products must also meet these federal standards. All chicken products must meet or exceed these safety standards set forth by FSIS in order to reach American consumers.

Federal inspectors are present at all times during operation in chicken processing plants. In a federally inspected slaughter operation, every bird is inspected and inspectors have the authority to stop production for food safety violations.

HACCP

Since 1996, the meat and poultry industries have been operating under Hazard Analysis Critical Control Point (HACCP), which is a systematic, science-based and preventive approach to food safety that addresses potential biological, chemical and physical contamination of food products. HACCP plans consist of measures to protect the food from unintentional contamination at critical control points. HACCP is used in the meat and poultry industry to identify potential food safety hazards, so that key actions can be taken to reduce or eliminate these risks.