The incidence of nonfatal occupational injuries and illnesses in the poultry sector, which includes slaughter and processing, continues to remain low, according to the 2010 Injury and Illness Report recently released by the Department of Labor’s Bureau of Labor Statistics (BLS).

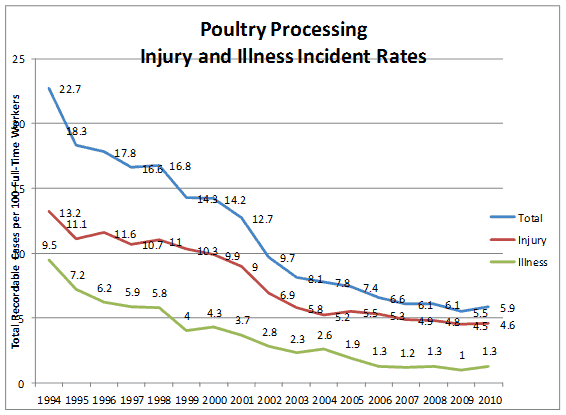

The total recordable poultry processing illness and injury rate for 2010 was 5.9 cases per 100 full-time workers (per year), up slightly from 5.5 in 2009 but down from 6.1 in 2008.

In terms of injuries per 100 full time workers, the poultry industry’s rate of 5.9 was below the rate of 6.9 for all animal slaughter and processing and statistically the same as the rate of 5.8 for the entire food manufacturing sector.

Poultry processing’s 2010 rate of 5.9 represents a 74 percent decrease from 1994 (the oldest data available on the BLS website), when the recorded rate was 22.7, demonstrating the enormous progress the industry has made in improving safety for its workforce.

The industry continues to work to improve its record in worker safety. Ongoing efforts include:

- Sharing non-competitive practices, culminating with the release of a whitepaper, Ergonomics in the Poultry Industry – A Review of 25 Years of Industry Efforts, which documents many of the industry’s efforts to improve worker safety;

- Partnering with the Georgia Tech Research Institute to develop an instrument to assess musculoskeletal disorder (MSD) risks in poultry tasks. The tool will measure upper extremity stresses associated with poultry deboning and cutting tasks, and provide quantitative data to help in workstation and tool redesign and process workflow improvements to reduce the stresses and strains associated with repetitive work;

- Continuing to work with equipment manufacturers and suppliers to improve machine guarding on new equipment and the provision of adequate disconnects to assist and facilitate proper lock out/tag out (LOTO) procedures; and

- Collaborating with personal protective equipment suppliers. This has led to improvements in cut resistance of protective handwear, reduced fogging issues with safety eyewear, and improved slip resistance in safety footwear to address lacerations, foreign objects/splashes and slip, trips and falls.